Did you know invisible dangers like toxic welding fumes and fire risks surround every arc welding project? Proper workspace setup isn’t just about skill—it’s about survival. Without careful planning, even experienced welders face life-threatening hazards daily.

Regulations from OSHA and NFPA demand a 35-foot safety zone between welding operations and flammable materials. Why? Because sparks can travel farther than you’d expect. That frayed cable or cluttered floor isn’t just messy—it’s a disaster waiting to happen.

Breathing issues like pneumonia or metal fume fever often start with poor ventilation. Modern guidelines require air controls for all welding tasks, even quick jobs. Your helmet, hood, and gloves matter, but so does clean airflow for everyone nearby to mitigate risks from welding fumes gases.

Think your workspace is safe? Let’s break down the steps to protect yourself and your team. From equipment checks to emergency plans, we’ll show you how to build a bulletproof safety routine in your working place.

Key Takeaways

- Toxic fumes from welding can cause long-term health issues like cancer and lung damage

- Keep 35 feet between welding operations and flammable materials to prevent fires

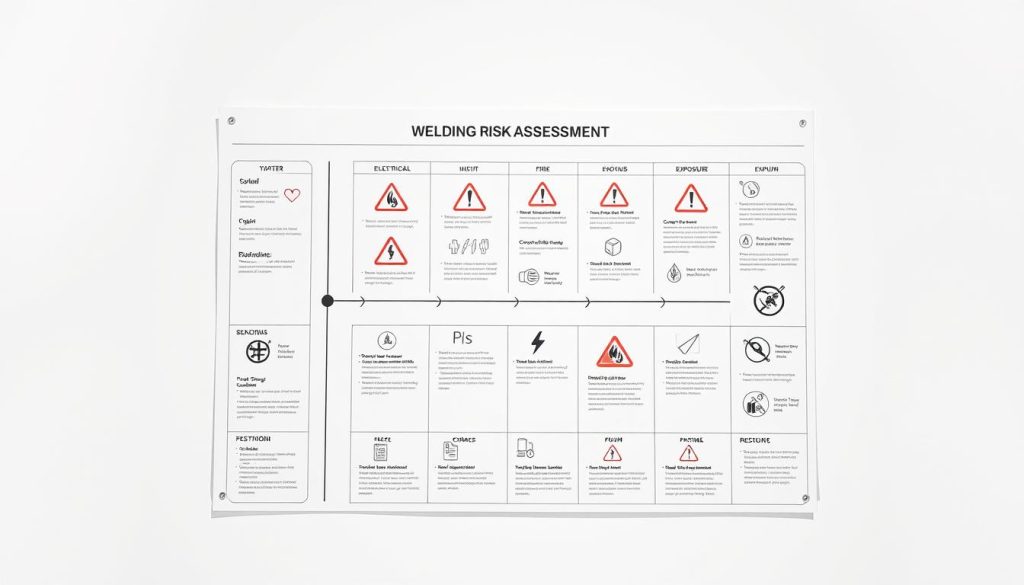

- Conduct risk assessments to spot electrical hazards and ventilation needs upfront

- Replace damaged equipment immediately—faulty gear causes most on-site accidents

- Use OSHA-approved personal protective equipment, including respirators and flame-resistant clothing during all welding tasks

- Install local exhaust systems to filter airborne particles in real time

- Refresh safety training quarterly to stay updated on changing workplace guidelines

Understanding Welding Safety and Work Area Fundamentals

What separates shops with zero accidents from those with constant safety reports? It starts with treating every spark like a potential emergency. Modern tools make jobs faster, but they can’t replace human judgment when risks appear.

One of the key preparation steps for arc welding when assessing the work area is ensuring it is free from flammable materials and has proper ventilation to maintain a safe and efficient welding environment.

The Importance of a Safe Environment

Think about the last time you saw a welding hood fog up mid-job. That momentary blindness could lead to disastrous choices without proper prep. Good lighting, clear walkways, and marked emergency exits form your first defense line in welding safety.

OSHA’s rules exist because someone learned the hard way. A frayed cable here or misplaced tank there caused real injuries. Regular equipment checks become second nature in shops where everyone values collective protection over speed. Understanding the safety data sheets related to welding fumes and gases is crucial in this workplace.

Overview of Essential Safety Guidelines

Why do some workers skip respirators for “quick” jobs? Complacency creeps in when tasks feel routine. Effective shops test air quality before starting—not after someone coughs. Remember, the requirements for safety in the vicinity of welding operations are critical.

Follow this three-step drill: 1) Scan for flammables 2) Check gear integrity 3) Confirm ventilation. Repeat it like brushing teeth—daily and without debate. Your safety health administration training only works if applied every single time. Keeping a safe distance from potential hazards is essential.

Ever notice how veteran welders tap cables twice? That’s habit born from close calls. Build your own rituals using proven guidelines, not shortcuts. Lives depend on it, especially in an environment where welding fumes and gases are prevalent.

Identifying Common Welding Hazards

Ever wonder why welders treat every spark like a potential emergency? The answer lies in hidden threats that linger long after the arc stops. Let’s uncover what really makes this trade dangerous beyond the obvious flames and bright lights.

Exposure to Fumes, Gases, and Radiation

That metallic smell during welding? It’s not just unpleasant—it’s deadly. Chromium, nickel oxides, and carbon monoxide drift through the air like invisible poison. Health organizations worldwide confirm no safe exposure level exists for these cancer-causing particles, highlighting the importance of welding safety in the workplace.

UV radiation acts like silent sunlight burns. Ever had sand in your eyes? Multiply that pain by ten—that’s arc-eye. Prolonged exposure can permanently cloud vision, turning skilled welders into disability statistics, emphasizing the need for proper health safety measures.

Risk of Fires, Electrical Shocks, and Burns

Think sparks only travel a few feet? Try thirty-five. A single ember can ignite materials three rooms away. Damp floors turn into death traps—live circuits can deliver shocks strong enough to stop hearts mid-beat, underscoring the hazards present in the welding environment.

Noise often gets ignored until hearing aids become necessary. Flame cutting operations regularly hit jet-engine loudness at 100+ decibels. Combine this with molten metal spatter, and you’ve got a recipe for instant third-degree burns, making the right safety equipment crucial.

Survival here means more than gloves and goggles. Comprehensive safety protocols separate temporary workers from career professionals. Because in welding, tomorrow’s health depends on today’s precautions, highlighting the need for proper risk assessment and mitigation strategies.

Assessing the Work Area for Arc Welding: Risk Assessment and Mitigation

What’s the first thing you check when entering a welding zone? Seasoned professionals know fire prevention starts before striking the arc. Let’s explore how to transform risky places into secure work environments that meet occupational safety health requirements.

Evaluating Flammable Materials and Fire Hazards

That paint can in the corner? It’s a bomb waiting to detonate. Maintain 35 feet of clearance around your operation—sparks can jump surprising distances. Relocate anything that burns: wood scraps, rags, or solvents to ensure welding safety.

Containers demand special attention. “Empty” drums often hold explosive vapors. Clean them with alkaline solutions until zero residue remains. Test with gas detectors before starting—better safe than sorry to avoid hazards related to fumes gases.

Assessing the Work Area for Arc Welding

| Hazard Type | Control Method | Effectiveness |

|---|---|---|

| Liquid flammables | Relocate beyond 35ft | 95% risk reduction |

| Metal dust | Wet floor treatment | 80% spark suppression |

| Electrical cords | Overhead routing | 70% trip prevention |

Implementing Risk Controls and Safety Protocols

Ever seen a welding curtain stop a fireball? Install flame-resistant barriers around your station. They contain sparks better than open space alone, enhancing overall safety.

Document every assessment step. This paper trail proves due diligence if accidents occur. Update records when weather changes—humidity affects spark behavior, impacting health safety.

Final tip: Treat your workspace like a kitchen. Remove grease, secure cords, and keep exits clear. Small precautions prevent big disasters, ensuring a safe place to work.

Setup Essentials: Equipment Maintenance and Worksite Organization

How many welders does it take to spot a frayed cable? Trick question—the right answer is every single one. Your gear’s condition directly impacts your survival odds. Let’s break down smart maintenance habits that keep you protected in the welding environment.

Before starting any project, assessing the workspace goes hand in hand with gathering necessary tools and equipment for arc welding, ensuring both safety and efficiency throughout the welding process.

Regular Inspection of Welding Gear and Cables

Veteran welders develop a sixth sense for worn connectors. Start each session with a 90-second check: twist cables to reveal hidden cracks, test clamps for tight grips, and sniff for burnt insulation. That loose ground clamp? It’s not just annoying—it could electrocute bystanders.

Replace electrodes showing green corrosion immediately. Moisture turns these into shock hazards. Store helmets in dry cases—a fogged lens causes more accidents than you’d think.

Proper Placement to Avoid Obstructions

Ever tripped over a hose mid-weld? Route cables along walls using magnetic hooks. Keep workstations 4 feet apart—this gives space to maneuver without tangling lines.

Color-code hoses: blue for argon, red for oxygen. Sounds simple? This trick prevents 40% of gas mix-ups reported last year. Use overhead reels for power cords—they stay clean and tangle-free.

Remember: organized spaces aren’t just tidy. They’re life-saving systems that let you focus on perfect beads, not potential disasters.

Ensuring Personal Protection and Comprehensive Training

Ever zipped up a jacket thinking it’s safe, only to find out later it’s a hazard? True safety combines smart gear choices with ongoing education. Let’s explore how proper PPE and updated training create an unbeatable defense against welding risks.

A safe and efficient setup starts with conducting pre-weld inspections and checks for arc welding, ensuring the work area is free from hazards and all equipment is in proper working condition before striking an arc.

Selecting Appropriate PPE for Welders

Your helmet does more than block sparks—it filters harmful rays that cause vision loss. Auto-darkening models adjust to different tasks, reducing eye strain. Pair it with side shields to stop debris from sneaking in.

Flame-resistant cotton beats synthetic fabrics every time. Why? Melted polyester sticks to skin like hot glue. Choose jackets without cuffs—openings trap molten metal. Don’t forget steel-toe boots with rubber soles. They ground stray currents while protecting toes.

The Role of Continuous Safety Training

New alloys mean new fumes. Monthly drills keep teams sharp on evolving threats. Practice emergency responses until they feel automatic—like muscle memory.

Review safety sheets before each project. They reveal hidden dangers in materials. Pair this with proper workspace organization for maximum protection.

Remember: Skills rust faster than metal. Refresh certifications yearly. Your life depends on staying current.

Optimizing Ventilation and Environmental Controls

Why do some welders breathe easy while others cough through their shifts? Clean air management makes the difference. Proper airflow setups stop toxic particles from becoming lifelong health issues.

Implementing Effective Ventilation Systems

Ever seen a shop where smoke vanishes like magic? That’s Local Exhaust Ventilation (LEV) in action. These systems suck fumes directly at the source—like a vacuum for dangerous particles. Portable units work for quick jobs, while ducted setups handle heavy-duty shops.

General fans just spread problems around. LEV captures 95% more contaminants than open windows. Position hoods 6-12 inches from the weld—close enough to grab fumes but out of your way.

Monitoring Air Quality and Fume Exposure

How clean is your shop’s air right now? Test kits measure metal levels you can’t see or smell. Swap filters when gauges hit yellow zones—don’t wait for red alerts.

Health checks catch issues early. One welder I know avoided lung damage because his annual test spotted nickel buildup. Pair screenings with proper respirators for complete protection.

Remember: Good airflow isn’t optional. It’s what lets skilled workers keep creating without sacrificing their health.

FAQ

How often should I check welding equipment for safety issues?

Inspect gear like Miller Electric welders and cables before each use. Look for frayed wires, loose connections, or damaged insulation. Monthly deep checks by a qualified technician ensure compliance with OSHA standards and promote overall welding safety.

What’s the best way to reduce fumes during arc welding?

Use local exhaust ventilation systems like fume extractors from brands like Lincoln Electric. Pair them with OSHA-approved respirators if air quality tests show fumes and gases exceed 5 mg/m³ exposure limits to ensure health safety.

Can regular work gloves replace welding-specific PPE?

No. Standard gloves melt under sparks. Use leather or flame-resistant gloves from Tillman or Caiman. Did you know 37% of hand injuries occur when workers skip proper PPE? Match gloves to your welding process – TIG requires thinner dexterity, while stick welding needs heavy-duty protection to mitigate risk.

How far should flammables be from the welding area?

Keep fuels, solvents, and combustible materials at least 35 feet away. Use Firefree fire blankets if relocation isn’t possible. A single spark can ignite vapors in seconds – always have ABC fire extinguishers nearby to ensure a safe work environment.

What training do new welders need for workplace safety?

OSHA mandates 10-hour OSHA 1910 training plus hands-on instruction in PPE use, hazard communication (review SDS sheets for metals like hexavalent chromium), and emergency procedures. Annual refreshers keep skills sharp – 68% fewer accidents occur in shops with ongoing training programs focused on health safety.

Why do my eyes still hurt with an auto-darkening helmet?

Cheap helmets (3M Speedglas or ESAB Sentinel A50 models. Check for proper shade settings – MIG welding typically needs shade 10-13. Still seeing spots? Get an eye exam; 22% of welders develop arc eye damage from reflected UV rays.

How hot does the work area get during prolonged welding?

Temperatures near joints can hit 3,000°F+. Use infrared thermometers to monitor surroundings. Install heat-resistant curtains like Steiner’s 16 oz. leather barriers if ambient temps exceed 90°F. Rotate crews every 2 hours – heat stress causes 30% of summer-related welding incidents, affecting both time and health safety.